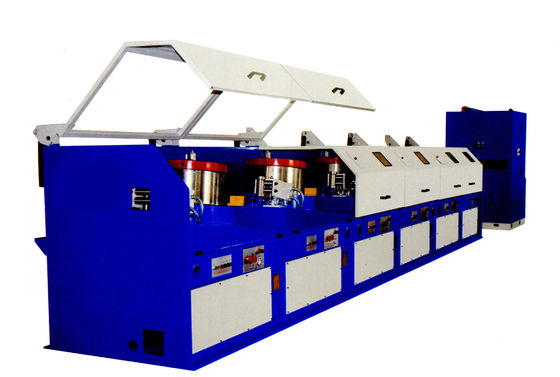

characteristics in high speed, low noise and high precision, they are also of 3 times service life than Z94-C series.

the machines stop automatically to prevent abrasive wear.

During wire feeding the automatic stop of the machines activates immediately once detecting curved wire, tangled wire and lack of wire so as to avoid accidents and save electrical energy.

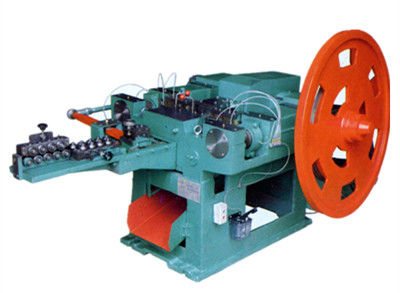

The Z94-3.4H and Z94-4.5H nail making machines are especially suitable for making clout nails and concrete nails. The kind of Series H machines are of solid, heavy structure and higher stability. With some modification, the machines can make special-shaped nails. Due to the introduction of nail points' chip remover, the high quality of clout and roofing nails are fully ensured.

What's more:

The rolling part of the machines applies the combination of bush bearing rolling and bearing rolling, which enhances the size stability of nail heads' formation and brings convenience to the maintenance of the machines. The main parts of the machines are made of high -quality steel, such as crankshaft, sliding block of heading device made of 40CrNiMo, drive bevel gear made of 20CrMoti and all heat treated, making the machines impact resistant, wear resistant and durable.

| TECHNICAL SPECIFICATIONS | |||

| Model | Unit | Z94-4.5H | Z94-3.4H |

| Max. dia. Of nail | mm | 4.5 | 3.7 |

| Min. dia. Of nail | mm | 2.8 | 1.8 |

| Max. length of nail | mm | 100 | 80 |

| Min. length of nail | mm | 50 | 20 |

| Designed capacity | pcs/min | 300 | 350 |

| Motor power | KW | 4 | 3 |

| Weight | kg | 3800 | 1800 |

| Overall dimensions(L*W*H) | mm | 3000*1600*1650 | 2400*1500*1500 |