Product Description:

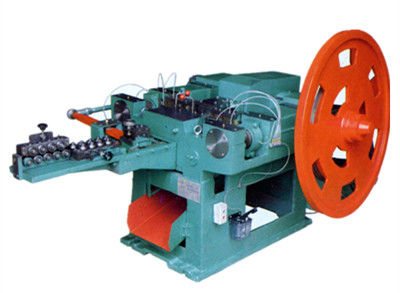

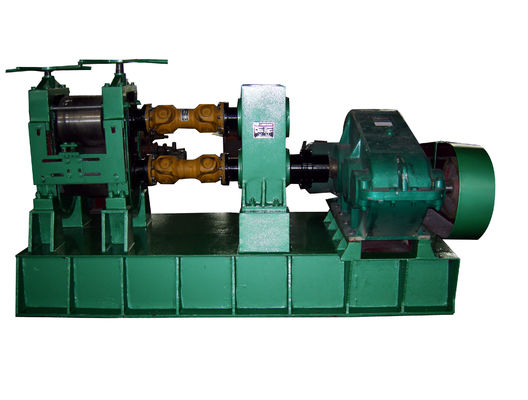

Introducing our top-of-the-line Wire Drawing Machines, a hot product in the market for wire making machinery enthusiasts. Designed for precision and efficiency, these machines are a must-have for any wire manufacturing facility.

With a focus on quality and performance, our Wire Drawing Machines are essential tools for producing high-quality wires. Whether you are working on industrial projects or crafting intricate designs, these machines deliver exceptional results every time.

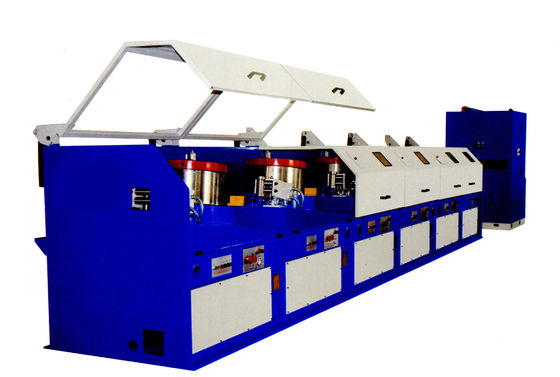

The Wire Drawing Machines are specifically designed for wire drawing lubricant, ensuring smooth operation and consistent output. The machines come equipped with advanced features to enhance the wire drawing process, making it easier and more efficient for operators.

Operating at voltages of 220V, 380V, or 440V and frequencies of 50Hz or 60Hz, these machines offer flexibility and compatibility with various power systems. This versatility allows for seamless integration into different manufacturing setups, providing convenience and ease of use.

Featuring a single working position roll, our Wire Drawing Machines are engineered for optimal performance and productivity. The roll position ensures precise wire drawing and coiling, resulting in uniform and high-quality wires every time.

Whether you are a seasoned professional or a beginner in the wire manufacturing industry, our Wire Drawing Machines are the perfect choice for achieving exceptional results. Invest in quality wire manufacturing equipment that is built to last and deliver outstanding performance.

Upgrade your wire manufacturing process with our Wire Drawing Machines and experience the difference in efficiency and quality. Say goodbye to manual wire drawing methods and embrace the future of wire manufacturing with our cutting-edge machines.

Don't compromise on quality and precision when it comes to wire manufacturing. Choose our Wire Drawing Machines for reliable performance, durability, and unmatched results. Take your wire manufacturing operations to the next level with our innovative and high-performance machines.

Features:

-

Product Name: Wire Drawing Machines

-

Showroom Location: Indonesia, Bangladesh, Malaysia

-

Frequency: 50Hz/60Hz

-

Marketing Type: Hot Product

-

Fan Power: 30W

-

Power Source: Electricity

Technical Parameters:

|

Guide Wheel Material

|

Stainless Steel

|

|

Usage

|

Wire Drawing Lubricant

|

|

Cooling System

|

Water Cooling

|

|

Roll Position

|

Single Working Position

|

|

Voltage

|

220V/380V/440V

|

|

Frequency

|

50Hz/60Hz

|

|

Marketing Type

|

Hot Product

|

|

Fan Power

|

30W

|

|

Showroom Location

|

Indonesia, Bangladesh, Malaysia

|

|

Power Source

|

Electricity

|

Applications:

Wire Drawing Machines are essential Wire Processing Equipment used in various industries for manufacturing wires of different diameters and materials. These machines are versatile and can be applied in a wide range of scenarios due to their efficient performance and reliable operation.

One of the key Product Application Occasions for Wire Drawing Machines is in wire production facilities where wires are manufactured for various industries such as construction, automotive, and electronics. These machines play a crucial role in the Wire Making Machinery process by drawing the wire through a series of dies to reduce its diameter and improve its quality.

Wire Drawing Machines are particularly suitable for businesses looking to enhance their wire production capabilities. With Voltage options of 220V, 380V, and 440V, these machines can be easily integrated into different power systems to meet the specific requirements of the production environment.

As a Hot Product in the market, Wire Drawing Machines are known for their high Fan Power of 30W, which ensures efficient cooling and optimal performance during operation. The Cooling System of these machines is designed for Water Cooling, making them energy-efficient and environmentally friendly.

Whether it's a small-scale wire manufacturing workshop or a large industrial plant, Wire Drawing Machines are a reliable choice for businesses seeking efficient Wire Making Machinery. Their Electricity as the Power Source makes them easy to operate and maintain, offering a cost-effective solution for wire production needs.

Customization:

Product Customization Services for Wire Drawing Machines:

Fan Power: 30W

Voltage: 220V/380V/440V

Cooling System: Water Cooling

Power Source: Electricity

Roll Position: Single Working Position

Keywords: Wire Coiling Machines, Wire Processing Equipment, Wire Draw Machines

Support and Services:

Our Product Technical Support and Services for Wire Drawing Machines include:

- Installation assistance and guidance

- Operational training for your staff

- Troubleshooting and maintenance support

- Upgrades and customization services

- Spare parts supply and replacement

- Regular maintenance schedules and service plans

Packing and Shipping:

Product Packaging:

The Wire Drawing Machines are carefully packaged to ensure safe delivery. Each machine is securely wrapped in protective materials to prevent any damage during transportation. The packaging is designed to withstand rough handling and long-distance shipping.

Shipping Information:

Once the order is placed, our team will process it promptly. The Wire Drawing Machines will be shipped using a reliable courier service with tracking information provided. Customers can expect their orders to be delivered within the specified timeframe, depending on their location.

FAQ:

Q: What is the maximum wire diameter that can be processed by the Wire Drawing Machines?

A: The Wire Drawing Machines can typically process wire diameters ranging from 10mm to 0.1mm, depending on the specific model.

Q: How many drawing dies come with the Wire Drawing Machines?

A: The number of drawing dies included with the Wire Drawing Machines varies by model, with some machines supporting multiple dies for different wire thicknesses.

Q: Can the Wire Drawing Machines operate at variable speeds?

A: Yes, most Wire Drawing Machines offer variable speed control to accommodate different wire drawing requirements and materials.

Q: Are the Wire Drawing Machines suitable for processing different types of metals?

A: Yes, Wire Drawing Machines are versatile and can handle various metals such as steel, copper, aluminum, and more.

Q: What safety features are included with the Wire Drawing Machines?

A: Wire Drawing Machines are equipped with safety mechanisms like emergency stop buttons, protective guards, and overload protection to ensure safe operation for users.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!