Product Description:

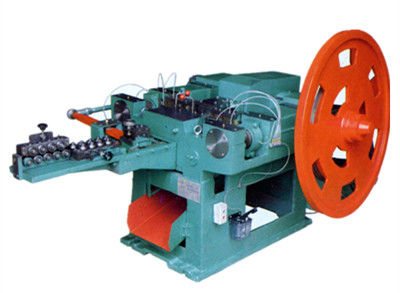

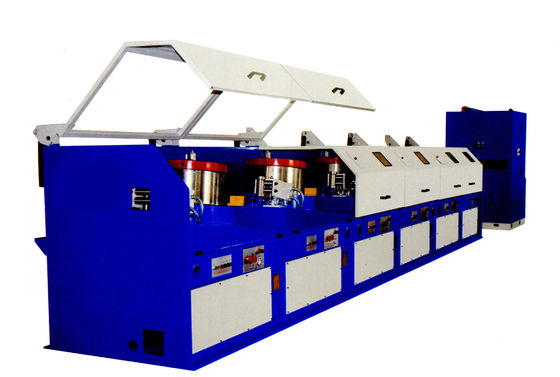

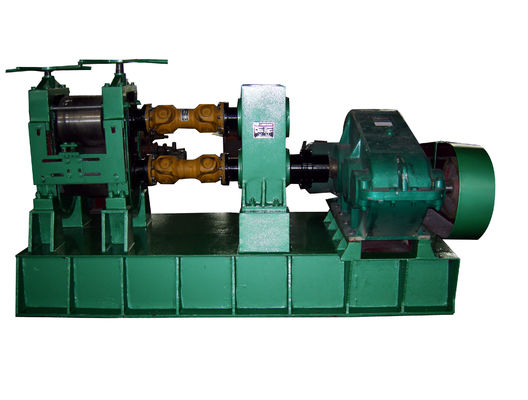

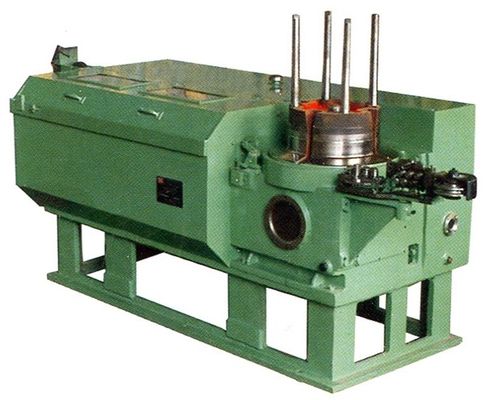

The Wire Drawing Machines are essential equipment for wire manufacturing processes, designed to efficiently draw wire to the desired diameter. These machines are versatile and reliable, suitable for various industries that require wire production.

Operating at a frequency of 50Hz/60Hz, the Wire Drawing Machines exhibit consistent performance and can be easily integrated into different production setups. The machines are equipped with a single working position for seamless operation, ensuring efficiency and precision in wire processing.

Available for viewing at showroom locations in Indonesia, Bangladesh, and Malaysia, customers have the opportunity to see the Wire Draw Machines in action and evaluate their capabilities firsthand. This accessibility allows for a better understanding of the machines' features and functionality.

With voltage options of 220V, 380V, and 440V, the Wire Drawing Machines can be customized to meet specific power requirements, offering flexibility for installation in various industrial environments. This adaptability ensures that the machines can be seamlessly integrated into existing production lines without any hassle.

The guide wheel material of the Wire Drawing Machines is constructed from high-quality stainless steel, providing durability and longevity to the equipment. Stainless steel is known for its corrosion resistance and strength, ensuring smooth wire drawing operations and minimal maintenance requirements.

In summary, the Wire Drawing Machines are indispensable Wire Making Machinery that offer efficient and precise wire processing capabilities. With a single working position, these machines deliver consistent performance at a frequency of 50Hz/60Hz, making them suitable for a wide range of industries. The machines are available for viewing at showroom locations in Indonesia, Bangladesh, and Malaysia, providing customers with firsthand experience of their features and functionality.

Operating at voltages of 220V, 380V, and 440V, the Wire Drawing Machines can be tailored to specific power requirements, ensuring seamless integration into diverse industrial settings. The guide wheel material made of stainless steel adds to the durability and reliability of the machines, making them a valuable asset for wire manufacturing processes.

Features:

-

Product Name: Wire Drawing Machines

-

Voltage: 220V/380V/440V

-

Marketing Type: Hot Product

-

Power Source: Electricity

-

Cooling System: Water Cooling

-

Roll Position: Single Working Position

Technical Parameters:

|

Cooling System

|

Water Cooling

|

|

Marketing Type

|

Hot Product

|

|

Guide Wheel Material

|

Stainless Steel

|

|

Voltage

|

220V/380V/440V

|

|

Usage

|

Wire Drawing Lubricant

|

|

Power Source

|

Electricity

|

|

Roll Position

|

Single Working Position

|

|

Frequency

|

50Hz/60Hz

|

|

Fan Power

|

30W

|

|

Showroom Location

|

Indonesia, Bangladesh, Malaysia

|

Applications:

Wire Drawing Machines are essential equipment used in various industries for wire processing tasks. These machines are versatile and can be used in a wide range of applications due to their efficient performance and reliable operation.

Product Application Occasions and Scenarios:

1. Industrial Wire Manufacturing:

Wire Drawing Machines play a crucial role in industrial settings where wires need to be produced efficiently and precisely. These machines are commonly used in wire making factories to draw out wire from metal rods and achieve the desired thickness.

2. Wire Coiling Machines Integration:

Wire Drawing Machines can be seamlessly integrated with Wire Coiling Machines for a complete wire processing solution. The combined use of these machines ensures a streamlined production process and high-quality wire products.

3. Wire Drawing Lubricant Application:

These machines are ideal for applying wire drawing lubricant during the manufacturing process. The lubricant helps in reducing friction and heat generation, resulting in smoother wire drawing operations and improved wire quality.

4. Showroom Demonstrations:

Wire Drawing Machines are often showcased in showrooms located in Indonesia, Bangladesh, and Malaysia. Prospective customers can witness the machines in action and understand their capabilities firsthand.

5. Custom Wire Processing Needs:

Industries with specific wire processing requirements can benefit from Wire Drawing Machines. These machines can be customized to meet different voltage specifications (220V/380V/440V) and frequency (50Hz/60Hz) standards, ensuring compatibility with various power sources.

6. Diverse Wire Making Machinery Applications:

Wire Drawing Machines are part of the broader category of wire making machinery. They are used in applications such as cable manufacturing, wire mesh production, and electrical wiring industries.

Overall, Wire Drawing Machines are versatile tools that find extensive use in wire processing operations across industries. With their ability to handle different wire materials and produce precise outputs, these machines are indispensable for achieving efficient and high-quality wire manufacturing processes.

Customization:

Product Customization Services for the Wire Coiling Machines:

Guide Wheel Material: Stainless Steel

Frequency: 50Hz/60Hz

Usage: Wire Drawing Lubricant

Cooling System: Water Cooling

Marketing Type: Hot Product

Support and Services:

Our Product Technical Support and Services for Wire Drawing Machines include:

- Installation assistance and guidance to ensure proper setup of the machine.

- Regular maintenance and servicing to keep the machine in optimal working condition.

- Troubleshooting support to address any technical issues or malfunctions promptly.

- Training programs for operators to enhance their knowledge and skills in using the machine effectively.

- Access to a dedicated support team for any inquiries or assistance required.

Packing and Shipping:

Product Packaging for Wire Drawing Machines:

- Each wire drawing machine is carefully packed in a sturdy cardboard box to ensure safe transportation.

- The machine components are securely wrapped in protective foam or bubble wrap to prevent any damage during shipping.

Shipping Information:

- We offer worldwide shipping for our wire drawing machines.

- Shipping costs may vary depending on the destination and shipping method selected.

FAQ:

Q: What is a wire drawing machine?

A wire drawing machine is a piece of equipment used to pull a wire rod through a series of drawing dies to reduce its diameter and increase its length for various industrial applications.

Q: What types of wires can be processed by wire drawing machines?

Wire drawing machines can process a wide range of materials including steel, copper, aluminum, and various alloys to produce wires of different diameters and qualities.

Q: What are the key features to consider when choosing a wire drawing machine?

Key features to consider include the machine's drawing capacity, speed, number of dies, material compatibility, ease of operation, and overall durability for long-term use.

Q: How do wire drawing machines contribute to the manufacturing industry?

Wire drawing machines play a crucial role in creating wires of precise diameters and lengths required for manufacturing products such as cables, wires, ropes, springs, and more.

Q: What maintenance practices are recommended for wire drawing machines?

Regular cleaning, lubrication of moving parts, inspection of dies, and adjustment of tension are essential maintenance practices to ensure optimal performance and longevity of wire drawing machines.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!