Product Description:

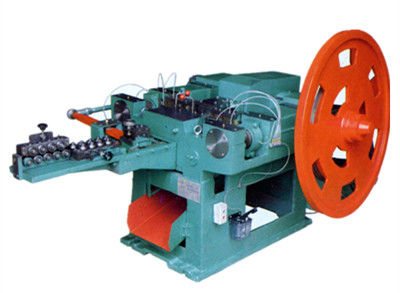

Are you in need of high-quality Wire Manufacturing Equipment for your business? Look no further than our top-of-the-line Wire Drawing Machines. Designed to meet the demands of wire manufacturing processes, these machines are equipped with advanced features to ensure efficiency and precision.

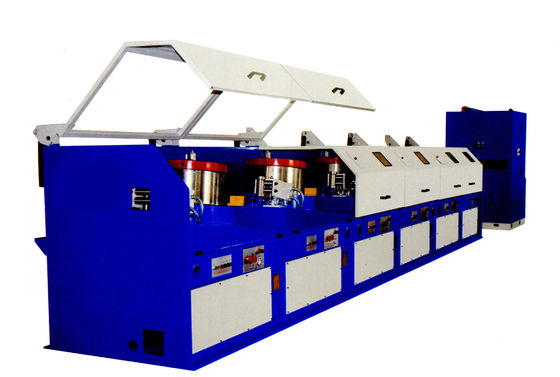

With a Fan Quantity of 6, our Wire Drawing Machines are built to handle heavy workloads with ease. The powerful fans ensure optimal cooling during operation, allowing for continuous use without overheating.

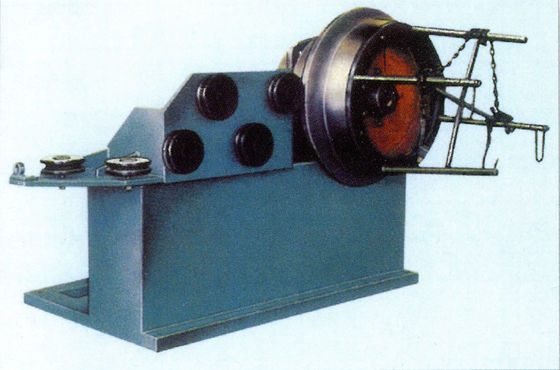

When it comes to Outlet Diameter, our machines offer a versatile range from 0.8mm to 5mm. This wide range allows for flexibility in wire production, making it suitable for various applications and requirements.

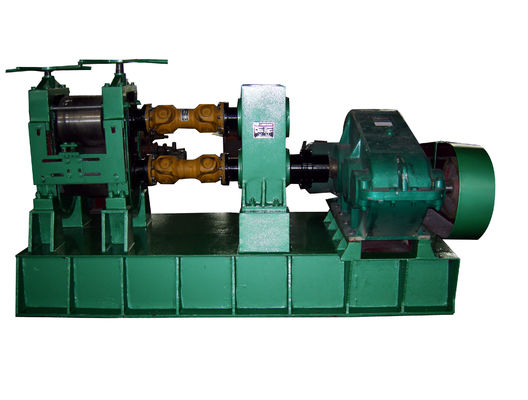

The Roll Position of our Wire Drawing Machines is designed for Single Working Position, simplifying the operation and maintenance process. This user-friendly design enhances productivity and reduces downtime, making it an ideal choice for busy manufacturing facilities.

One of the standout features of our Wire Drawing Machines is the Wire Diameter Range it can accommodate. From 0.5mm to 10mm, these machines can handle a wide range of wire thicknesses, catering to diverse production needs and specifications.

Looking to minimize disruptions in your workspace? Our Wire Drawing Machines boast a Low Noise Level, ensuring a quiet and comfortable working environment. Say goodbye to noisy machinery and hello to a more peaceful and efficient production floor.

Investing in top-notch Wire Manufacturing Equipment is crucial for achieving consistent and high-quality wire products. Our Wire Drawing Machines are the epitome of reliability and performance, making them a valuable addition to any wire processing facility.

Whether you are in the automotive, construction, or electronics industry, our Wire Drawing Machines are designed to meet the stringent demands of wire manufacturing. Trust in our equipment to deliver exceptional results and elevate your production capabilities.

Upgrade your wire processing operations with our advanced Wire Drawing Machines today. Experience the efficiency, precision, and durability that only top-quality wire manufacturing equipment can provide.

Features:

-

Product Name: Wire Drawing Machines

-

Key Selling Points: Low Noise Level

-

Power Source: Electric

-

Roll Position: Single Working Position

-

Control System: PLC

-

Outlet Diameter: 0.8~5mm

Technical Parameters:

|

Key Selling Points

|

Low Noise Level

|

|

Outlet Diameter

|

0.8~5mm

|

|

Wire Diameter Range

|

0.5mm-10mm

|

|

Control System

|

PLC

|

|

Color

|

Customised

|

|

Fan Quantity

|

6

|

|

Material

|

Steel

|

|

Roll Position

|

Single Working Position

|

|

Inlet Diameter

|

0.75~2.5mm

|

|

Power

|

18.5-30KW

|

Applications:

The Wire Drawing Machine is a versatile piece of equipment that plays a crucial role in the wire manufacturing industry. With its ability to process steel materials and handle wire diameters ranging from 0.5mm to 10mm, this machine is essential for various applications in the production of wires.

One of the primary product application occasions for the Wire Drawing Machine is in wire coiling machines. This machine is used to draw steel wires to the desired diameter before they are sent to wire coiling machines for further processing. The Wire Drawing Machine's precise control system, which includes a PLC, ensures accurate and consistent wire diameter throughout the drawing process, making it an ideal choice for wire coiling operations.

With its capability to handle a wide range of wire diameters, the Wire Drawing Machine is also suitable for various wire manufacturing equipment scenarios. Whether it's producing thin wires with a diameter of 0.5mm or thicker wires up to 10mm, this machine can meet the demands of different manufacturing processes. The machine's six fan quantity further enhances its efficiency by providing optimal cooling during the drawing process, ensuring high-quality wire production.

Moreover, the Wire Drawing Machine's versatility is evident in its ability to accommodate different inlet diameters ranging from 0.75mm to 2.5mm. This flexibility allows manufacturers to work with various wire sizes and materials, making the machine a valuable asset in wire manufacturing facilities.

Customization:

Our Product Customization Services for the Wire Drawing Machines include:

- Wire Diameter Range: 0.5mm-10mm

- Control System: PLC

- Power: 18.5-30KW

- Material: Steel

- Outlet Diameter: 0.8~5mm

Enhance your Wire Processing Equipment with our customizable options for Wire Making Machinery. Upgrade your Wire Coiling Machines to meet your specific needs.

Support and Services:

Our Product Technical Support and Services for Wire Drawing Machines include:

- Installation and setup guidance

- Training for operators and maintenance staff

- Troubleshooting assistance for technical issues

- Regular maintenance and servicing

- Spare parts availability and ordering

- Upgrades and enhancements for improved performance

Packing and Shipping:

Product Packaging for Wire Drawing Machines:

The Wire Drawing Machine will be carefully packaged in a sturdy cardboard box to ensure safe transportation.

Shipping Information:

We offer worldwide shipping for the Wire Drawing Machines. Shipping costs may vary depending on the destination. Please allow 3-5 business days for processing and handling before the product is shipped out.

FAQ:

Q: What is a wire drawing machine?

A wire drawing machine is a piece of equipment used in the manufacturing process to pull wire through a series of dies to reduce its diameter.

Q: What types of wire can be processed with a wire drawing machine?

Wire drawing machines can process various types of materials, including steel, aluminum, copper, and other metal alloys.

Q: What are the key features to consider when choosing a wire drawing machine?

Key features to consider include the number of drawing dies, speed control options, motor power, material compatibility, and overall build quality.

Q: How does a wire drawing machine contribute to the wire production process?

A wire drawing machine helps in reducing the diameter of wire by pulling it through a series of dies, ensuring uniform thickness and improving the wire's strength and surface finish.

Q: What maintenance tasks are recommended for wire drawing machines?

Regular cleaning, lubrication of moving parts, inspection of dies for wear, and monitoring of motor performance are essential maintenance tasks to ensure the optimal functioning of a wire drawing machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!