Product Description:

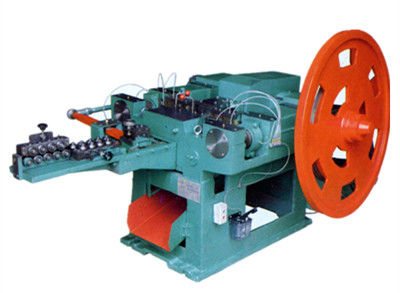

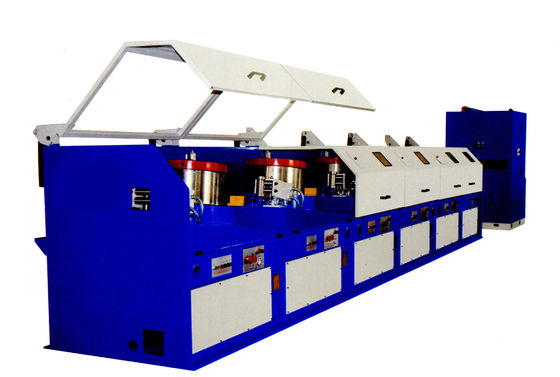

Introducing our top-of-the-line Wire Drawing Machines, essential wire manufacturing equipment designed to meet the demands of modern industrial settings. Powered by electricity, these machines offer efficiency and reliability for a seamless wire production process.

One of the key selling points of our Wire Drawing Machines is their remarkably low noise level, ensuring a quiet working environment and reducing disturbances in the workplace. This feature enhances overall productivity and operator comfort, making these machines a valuable asset for any wire manufacturing facility.

Equipped with a single working position for roll placement, our Wire Drawing Machines are built for convenience and ease of use. The streamlined design allows for efficient operation and maintenance, maximizing productivity and minimizing downtime.

With overall dimensions of 2600 X 1300 X 1350mm, these machines offer a compact footprint without compromising on performance. The sleek and ergonomic design makes them suitable for various industrial settings, providing flexibility in installation and operation.

Furthermore, the Wire Drawing Machines come with six high-quality fans, ensuring optimal cooling and ventilation during operation. The fan quantity of 6 enhances the machines' efficiency and longevity, allowing for continuous and reliable performance in wire manufacturing processes.

Invest in our Wire Drawing Machines today and experience the superior quality, efficiency, and reliability that these wire manufacturing equipment provide. With their electric power source, low noise level, single working position for roll placement, compact dimensions, and six fans for enhanced cooling, these machines are the ideal choice for modern industrial wire production facilities.

Features:

- Product Name: Wire Drawing Machines

- Key Selling Points: Low Noise Level

- Color: Customised

- Roll Position: Single Working Position

- Power: 18.5-30KW

- Fan Quantity: 6

Technical Parameters:

| Outlet Diameter |

0.8~5mm |

| Control System |

PLC |

| Roll Position |

Single Working Position |

| Wire Diameter Range |

0.5mm-10mm |

| Material |

Steel |

| Key Selling Points |

Low Noise Level |

| Color |

Customised |

| Dimensions |

1500mm X 1000mm X 1200mm |

| Power |

18.5-30KW |

| Fan Quantity |

6 |

Applications:

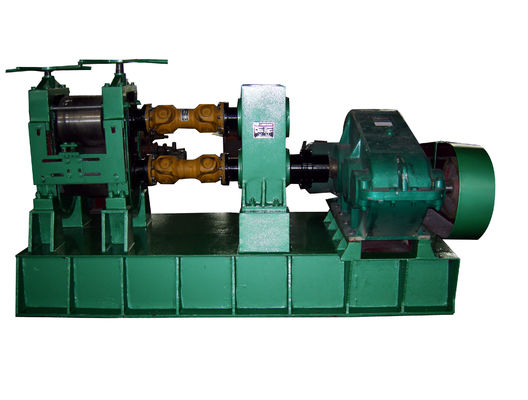

Wire Drawing Machines, also known as Wire Draw Machines, are essential wire processing equipment utilized in various industries for transforming wire rods into different diameters of wire. These machines are commonly used in scenarios requiring precise wire drawing processes.

The Product Application Occasions and Scenarios for Wire Drawing Machines are diverse due to their versatile nature. These machines find applications in industries such as construction, manufacturing, automotive, and electrical, where wire processing is a crucial part of the production process.

With a color that can be customized to fit specific preferences, Wire Drawing Machines made of steel offer durability and reliability in demanding industrial environments. The single working position roll design of these machines ensures efficient wire processing operations.

Measuring at 2600 X 1300 X 1350mm in overall dimensions, Wire Drawing Machines are compact yet capable of handling various wire drawing tasks effectively. Their electric power source makes them suitable for use in facilities with easy access to power outlets.

Wire Drawing Machines are ideal for applications where wire processing precision is paramount, such as the production of wires for electrical cables, fencing, construction materials, and automotive components. These machines excel in scenarios requiring consistent wire diameter and smooth surface finish.

Whether it's in a busy manufacturing plant or a specialized wire drawing facility, Wire Drawing Machines play a crucial role in meeting the demands of diverse wire processing tasks. Their efficiency, reliability, and customizable features make them a valuable asset in the production process.

Customization:

Product Customization Services for Wire Drawing Machines

Material: Steel

Inlet Diameter: 0.75~2.5mm

Power: 18.5-30KW

Overall Dimensions: 2600 X 1300 X 1350mm

Outlet Diameter: 0.8~5mm

Keywords: Wire Draw Machines, Wire Manufacturing Equipment, Wire Coiling Machines

Support and Services:

Our Product Technical Support and Services for Wire Drawing Machines include:

- Installation assistance to ensure proper setup and operation.

- Training programs for operators and maintenance staff to optimize performance.

- Troubleshooting guidance and remote assistance to address any issues that may arise.

- Regular maintenance and servicing to prolong the lifespan of the machine.

- Upgrades and customization options to meet specific production requirements.

Packing and Shipping:

Product Packaging and Shipping for Wire Drawing Machines:

Our Wire Drawing Machines are carefully packaged to ensure safe delivery to our customers. Each machine is securely wrapped in protective materials to prevent any damage during transportation. Additionally, the machines are placed in sturdy boxes to further protect them during shipping.

For shipping, we partner with reliable carriers to deliver the machines to your desired location. Our team ensures that the machines are properly loaded and secured for transit to minimize the risk of any mishaps during transportation. You can track your shipment using the provided tracking information to know the status of your order.

FAQ:

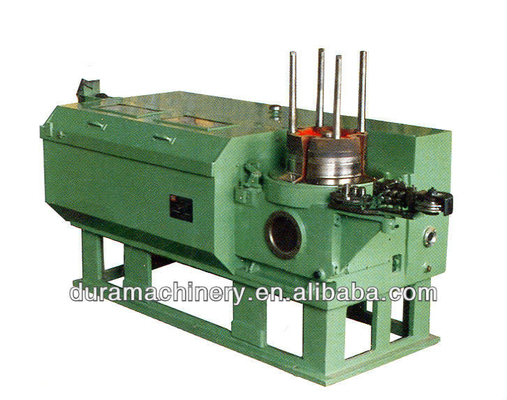

Q: What is a wire drawing machine?

A wire drawing machine is a piece of equipment used to pull a wire or rod through a series of dies to reduce its diameter and increase its length.

Q: What are the main components of a wire drawing machine?

The main components of a wire drawing machine typically include a capstan, die box, drawing dies, spooler, and drive motor.

Q: What types of wires can be processed using a wire drawing machine?

Wire drawing machines can be used to process various types of wires, including steel wire, copper wire, aluminum wire, and alloy wire.

Q: What are the key factors to consider when choosing a wire drawing machine?

Key factors to consider when choosing a wire drawing machine include the wire diameter range, drawing speed, number of dies, motor power, and overall build quality.

Q: How can I maintain a wire drawing machine for optimal performance?

To maintain a wire drawing machine for optimal performance, regular cleaning, lubrication of moving parts, inspection of dies, and monitoring of tension levels are recommended.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!