Product Description:

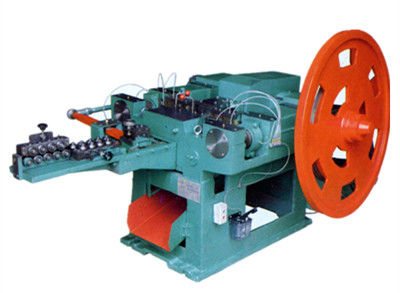

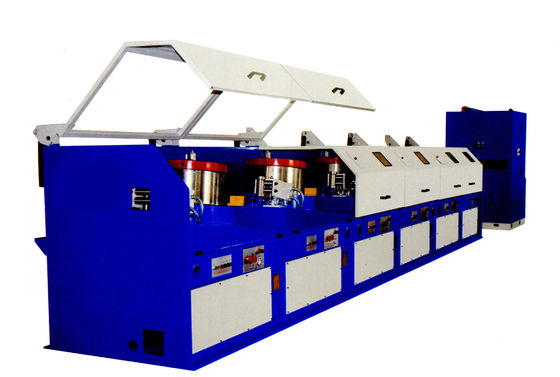

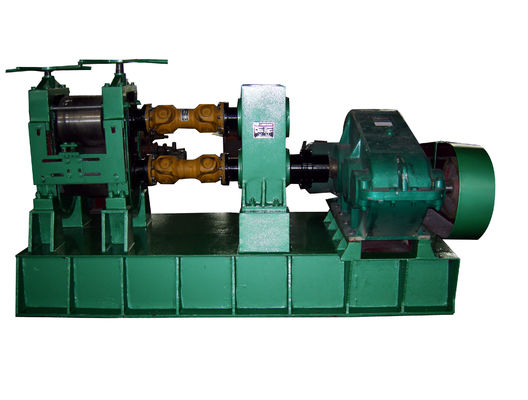

The Wire Drawing Machines offered by our company are essential wire processing equipment designed to meet the needs of wire manufacturers. These machines are built with high-quality steel materials to ensure durability and long-lasting performance. Powered by electricity, our Wire Drawing Machines provide efficient and consistent operation for producing various wire diameters.

With a single working position roll configuration, our Wire Drawing Machines are user-friendly and easy to operate. The simplified design allows for precise control over the wire drawing process, making it suitable for both small-scale and large-scale wire manufacturing operations.

One of the key features of our Wire Drawing Machines is their wide wire diameter range capability. These machines can effectively draw wires with diameters ranging from 0.5mm to 10mm, making them versatile and adaptable to different production requirements. Whether you need fine wires for delicate applications or thicker wires for robust products, our machines can handle the task with precision.

Our Wire Drawing Machines also offer customization options in terms of color, allowing you to choose a finish that suits your preferences or corporate branding. The ability to customize the color adds a personalized touch to the machines, making them not only functional but also visually appealing in your manufacturing facility.

As a leading provider of Wire Making Machinery, we take pride in delivering reliable and efficient solutions for wire manufacturers around the world. Our Wire Drawing Machines are built to meet the highest industry standards, ensuring quality output and operational excellence. Whether you are producing wires for construction, automotive, electronics, or any other industry, our machines are designed to enhance your wire manufacturing process.

In conclusion, our Wire Drawing Machines are a must-have investment for any wire manufacturer looking to optimize their production capabilities. With their steel construction, electric power source, single working position roll setup, wide wire diameter range, and customizable color options, these machines offer a complete package for efficient and effective wire drawing operations. Trust in our Wire Making Machinery to elevate your wire manufacturing process and meet the demands of your customers with precision and quality.

Features:

-

Product Name: Wire Drawing Machines

-

Outlet Diameter: 0.8~5mm

-

Control System: PLC

-

Fan Quantity: 6

-

Roll Position: Single Working Position

-

Power Source: Electric

Technical Parameters:

|

Key Selling Points

|

Low Noise Level

|

|

Overall Dimensions

|

2600 X 1300 X 1350mm

|

|

Outlet Diameter

|

0.8~5mm

|

|

Fan Quantity

|

6

|

|

Wire Diameter Range

|

0.5mm-10mm

|

|

Roll Position

|

Single Working Position

|

|

Dimensions

|

1500mm X 1000mm X 1200mm

|

|

Material

|

Steel

|

|

Power Source

|

Electric

|

|

Color

|

Customised

|

Applications:

Wire Drawing Machines, also known as Wire Draw Machines, are essential wire processing equipment used in various industries for shaping and reducing the diameter of metal wires. With dimensions of 1500mm X 1000mm X 1200mm, these machines are compact and versatile, suitable for different work environments.

The single working position of the Wire Drawing Machines allows for efficient operation and precise control over the wire drawing process. Made from durable steel material, these machines are robust and long-lasting, ensuring reliable performance in demanding industrial settings.

Powered by electricity, Wire Drawing Machines provide consistent and high-speed wire drawing capabilities, making them ideal for mass production and high-volume wire processing tasks. The electric power source also offers energy efficiency and cost-effectiveness compared to other power sources.

With an outlet diameter range of 0.8~5mm, Wire Drawing Machines are suitable for processing various wire thicknesses, offering flexibility in production requirements. Whether producing fine wires for electronics or thicker wires for construction, these machines can meet a wide range of wire drawing needs.

The versatility and reliability of Wire Drawing Machines make them suitable for a variety of application occasions and scenarios. Industries such as manufacturing, construction, automotive, and electronics benefit from the precision and efficiency of these machines in producing high-quality wires for different purposes.

Whether used in small-scale workshops or large-scale production facilities, Wire Drawing Machines play a crucial role in enhancing productivity and maintaining consistent wire quality. Their compact design, single working position, steel construction, electric power source, and adjustable outlet diameter make them a valuable asset in the wire processing industry.

Customization:

For our Wire Drawing Machines, we offer Product Customization Services to meet your specific requirements:

- Outlet Diameter: 0.8~5mm

- Material: Steel

- Inlet Diameter: 0.75~2.5mm

- Roll Position: Single Working Position

- Fan Quantity: 6

Customize your Wire Manufacturing Equipment with our Wire Draw Machines product to enhance your Wire Processing Equipment setup.

Support and Services:

Our Product Technical Support and Services for Wire Drawing Machines include:

- Installation assistance

- Training for machine operators

- Troubleshooting guidance

- Regular maintenance schedules

- Spare parts availability

- Upgrade options for enhanced performance

Packing and Shipping:

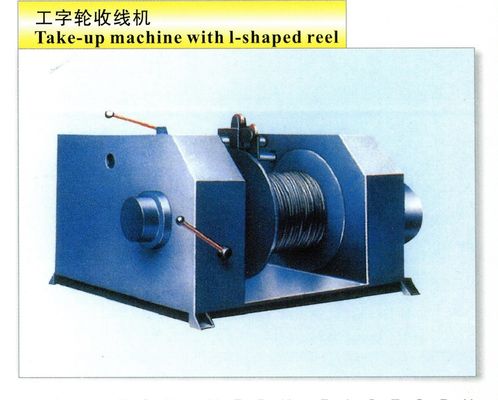

Product Name: Wire Drawing Machine

Description: Our Wire Drawing Machine is designed for efficient wire drawing operations, making it ideal for various industries.

Package Includes: Wire Drawing Machine, Instruction Manual

Packaging: The Wire Drawing Machine is securely packed in a sturdy cardboard box to prevent any damage during transit.

Shipping: We offer fast and reliable shipping services to ensure your Wire Drawing Machine reaches you safely and on time.

FAQ:

Q: What is a wire drawing machine?

A wire drawing machine is a piece of equipment used to pull wire through a series of dies to reduce its diameter and increase its length.

Q: What are the key components of a wire drawing machine?

The key components of a wire drawing machine include the drawing die, wire drawing drum, wire drawing capstan, and wire drawing lubricant system.

Q: What types of wire can be processed with a wire drawing machine?

Wire drawing machines can process various types of wire, including steel wire, aluminum wire, copper wire, and alloy wire.

Q: What are the main applications of wire drawing machines?

Wire drawing machines are commonly used in industries such as wire manufacturing, cable production, steel wire processing, and electrical wire production.

Q: How can I ensure the optimal performance of a wire drawing machine?

To ensure optimal performance, regular maintenance of the machine, proper lubrication of components, and monitoring of wire tension are essential. It is also important to follow the manufacturer's guidelines for operation and maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!