Product Description:

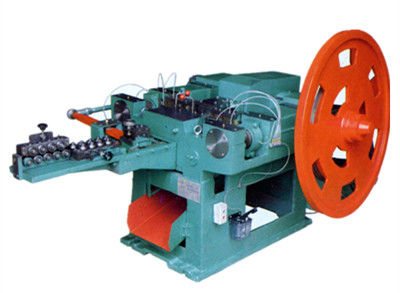

Are you in need of reliable Wire Manufacturing Equipment for your business operations? Look no further than our state-of-the-art Wire Drawing Machines. Designed with precision and efficiency in mind, our Wire Drawing Machines are the perfect solution for businesses looking to enhance their wire processing capabilities.

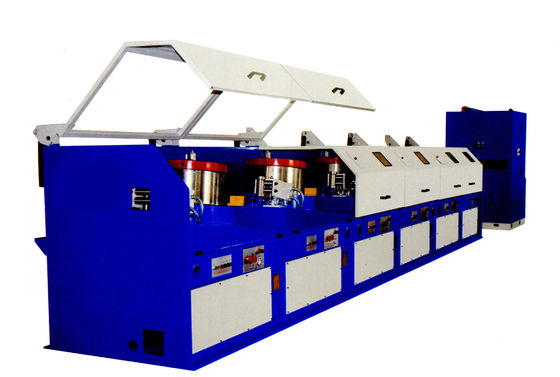

With a power range of 18.5-30KW, our Wire Drawing Machines offer the necessary strength and performance to handle a wide range of wire materials. Whether you are working with copper, aluminum, or other materials, our machines are up to the task. The power source for our machines is electric, ensuring consistent and reliable operation to meet your production needs.

When it comes to wire diameter, our Wire Drawing Machines excel with an inlet diameter ranging from 0.75mm to 2.5mm. This versatility allows you to process various wire sizes with ease, making our machines a valuable addition to any wire manufacturing facility. The wire diameter range supported by our machines is impressive, spanning from 0.5mm to 10mm, giving you the flexibility to work with a wide range of wire thicknesses.

Equipped with a sophisticated PLC control system, our Wire Drawing Machines offer advanced automation and monitoring capabilities. The PLC system ensures precise control over the wire drawing process, allowing you to achieve consistent results and efficient production runs. With user-friendly interfaces and intuitive controls, operating our machines is both convenient and efficient.

Investing in our Wire Drawing Machines means investing in the future of your wire manufacturing operations. With their superior performance, versatility, and advanced control system, our machines are the ideal choice for businesses seeking to optimize their wire processing capabilities. Whether you are producing wires for electrical applications, construction projects, or other industrial uses, our Wire Drawing Machines are equipped to meet your needs.

Don't settle for subpar wire manufacturing equipment when you can elevate your operations with our high-quality Wire Drawing Machines. Experience the difference that precision engineering and advanced technology can make in your production processes. Upgrade your wire processing capabilities today with our top-of-the-line Wire Drawing Machines.

Features:

-

Product Name: Wire Drawing Machines

-

Roll Position: Single Working Position

-

Fan Quantity: 6

-

Outlet Diameter: 0.8~5mm

-

Overall Dimensions: 2600 X 1300 X 1350mm

-

Inlet Diameter: 0.75~2.5mm

Technical Parameters:

|

Inlet Diameter

|

0.75~2.5mm

|

|

Power Source

|

Electric

|

|

Overall Dimensions

|

2600 X 1300 X 1350mm

|

|

Fan Quantity

|

6

|

|

Roll Position

|

Single Working Position

|

|

Material

|

Steel

|

|

Dimensions

|

1500mm X 1000mm X 1200mm

|

|

Key Selling Points

|

Low Noise Level

|

|

Outlet Diameter

|

0.8~5mm

|

|

Control System

|

PLC

|

Applications:

Wire Drawing Machines are versatile and essential equipment used in a wide range of industries for various applications. With an Inlet Diameter ranging from 0.75mm to 2.5mm and an Outlet Diameter from 0.8mm to 5mm, these machines are ideal for wire drawing processes in the manufacturing of different types of wires.

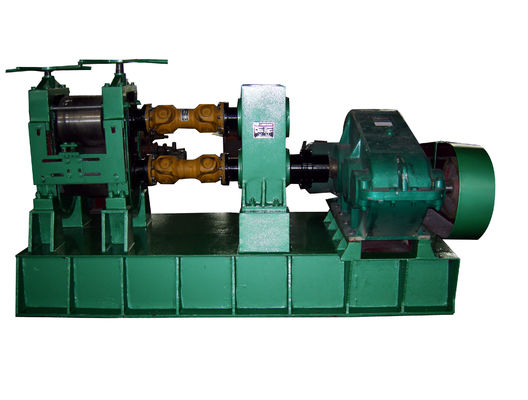

One of the primary Product Application Occasions for Wire Drawing Machines is in the production of Wire Making Machinery. These machines are crucial for drawing and shaping wires of different sizes and materials to meet the specific requirements of wire making equipment used in industries such as electrical, construction, and automotive.

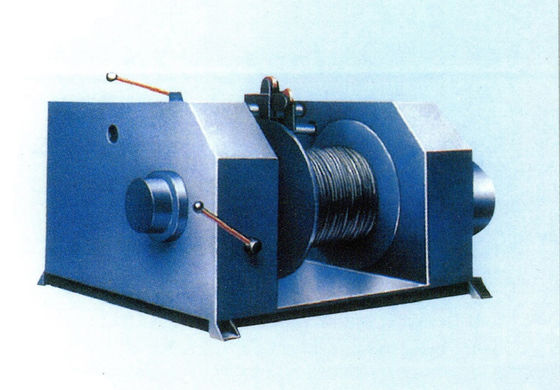

Wire Drawing Machines are also commonly used in Wire Coiling Machines applications. By drawing the wire through a series of dies to reduce its diameter and improve its quality, these machines enable the production of coils that are used in various applications such as springs, cables, and fencing.

Another important scenario for utilizing Wire Draw Machines is in industries requiring precise wire diameter control. With features such as 6 Fan Quantity for efficient cooling, Power ranging from 18.5KW to 30KW, and a sophisticated Control System like PLC, these machines are suitable for applications where consistent wire diameter and quality are critical.

Whether it's for Wire Making Machinery, Wire Coiling Machines, or other wire-related applications, Wire Drawing Machines play a vital role in the manufacturing process. Their ability to efficiently draw and shape wires to meet specific requirements makes them indispensable equipment in industries that rely on high-quality wires for their products.

Customization:

For our Wire Drawing Machines, we offer comprehensive Product Customization Services to meet your unique requirements:

- Outlet Diameter: 0.8~5mm

- Roll Position: Single Working Position

- Control System: PLC

- Power: 18.5-30KW

- Inlet Diameter: 0.75~2.5mm

Enhance your wire processing capabilities with our tailored solutions for Wire Drawing Machines, ensuring efficiency and precision in your operations.

Support and Services:

Our Product Technical Support and Services for Wire Drawing Machines include:

- Installation assistance and training for optimal setup

- Troubleshooting and diagnostics to address any issues

- Regular maintenance and servicing to ensure peak performance

- Upgrades and enhancements to keep your equipment up-to-date

- Technical consultations for customized solutions

- On-site support for urgent technical matters

Packing and Shipping:

Product Packaging for Wire Drawing Machines:

This Wire Drawing Machine is carefully packaged to ensure safe delivery. Each machine is wrapped in protective foam and placed in a sturdy cardboard box to prevent any damage during transportation.

Shipping Information:

We offer worldwide shipping for our Wire Drawing Machines. Once your order is confirmed, the machine will be carefully packed and shipped within 2 business days. You will receive a tracking number to monitor the delivery status of your package.

FAQ:

Q: What is a wire drawing machine?

A wire drawing machine is a piece of equipment used in the manufacturing industry to pull wires through a series of dies to reduce their diameter for various applications.

Q: What types of wires can be processed with a wire drawing machine?

Wire drawing machines are versatile and can process various types of wires including steel, copper, aluminum, and alloy wires.

Q: What are the key features to look for in a wire drawing machine?

Key features to consider when choosing a wire drawing machine include drawing speed, number of dies, motor power, material handling capacity, and ease of maintenance.

Q: How do I maintain a wire drawing machine?

To maintain a wire drawing machine, regular cleaning of dies and lubrication of moving parts is essential. Additionally, periodic inspections and adjustments should be carried out to ensure optimal performance.

Q: What safety precautions should be followed when operating a wire drawing machine?

Operators should wear appropriate protective gear such as gloves and safety goggles when operating a wire drawing machine. Additionally, proper training on machine operation and emergency procedures should be provided to all personnel.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!