Wire Drawing Machines are used in a wide range of industries, including:

Applications

Wire Drawing Machines are used in a wide range of industries, including:

-

Electrical Industry

Production of copper and aluminum wires for electrical cables, transformers, and wiring systems.

-

Automotive Industry

Manufacturing of wire for springs, control cables, tire reinforcements, and fasteners.

-

Construction

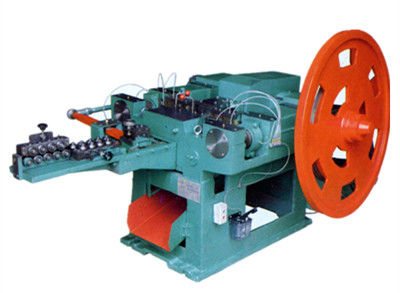

Production of nails, binding wires, steel wires for reinforcement, and fencing materials.

-

Telecommunication

Drawing fine wires for fiber optic cables and signal transmission lines.

-

General Manufacturing

Wire production for screws, bolts, industrial mesh, and hardware components.

electing the right Wire Drawing Machine depends on several key factors, including your production needs, material type, and required wire specifications. Here are the main considerations to help you choose the best machine for your application:

1. Material Type

Different metals require different machine configurations:

-

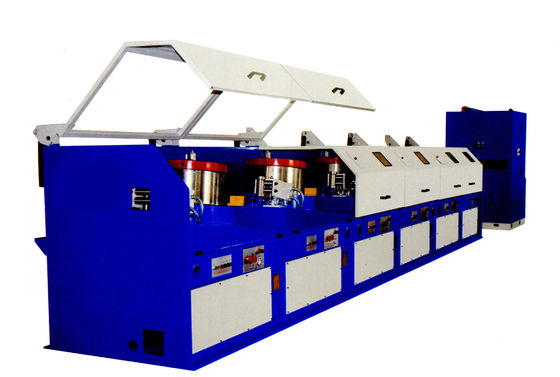

Copper & Aluminum: Prefer wet wire drawing machines for better surface finish and reduced heat generation.

-

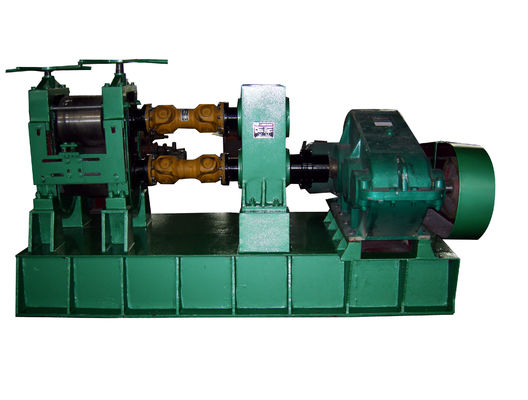

Steel (Low/High Carbon, Stainless): Dry wire drawing machines are more suitable due to stronger materials and higher friction.

-

Alloys or Specialty Metals: May require customized die materials and cooling systems.

2. Wire Diameter Range

Choose a machine that supports your required input and output wire diameters. Machines vary by:

Larger reductions require multi-pass machines with more drawing dies.

3. Production Volume

-

Small to Medium Scale: A single block wire drawing machine is suitable for lower output and simpler operations.

-

Large Scale/Industrial Use: Choose a multi-block or continuous wire drawing machine for high-speed and high-capacity production.

4. Surface Finish and Precision Requirements

If your application demands smooth surface finish and tight tolerance, opt for:

5. Automation and Control

For efficiency and ease of use:

-

Select machines with PLC or HMI control systems

-

Look for features such as automatic coiling, fault alarms, and speed synchronization

6. Lubrication System

-

Wet Lubrication: Better cooling, suitable for non-ferrous wires and fine wire drawing

-

Dry Lubrication: Lower maintenance, suitable for steel and heavy-duty applications

7. Budget and After-Sales Support

-

Consider your budget along with long-term operating costs (energy, spare parts, maintenance).

-

Choose a manufacturer with strong technical support, spare parts availability, and customization services.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!