Automatic Clothes Wire Hanger Making Machine Boosts Efficiency in Laundry Hanger Production

As global garment and laundry industries continue to expand, automation has become essential for improving production efficiency and reducing labor costs. The new Automatic Clothes Wire Hanger Making Machine from APEX Machinery provides a modern and reliable solution for high-speed hanger manufacturing.

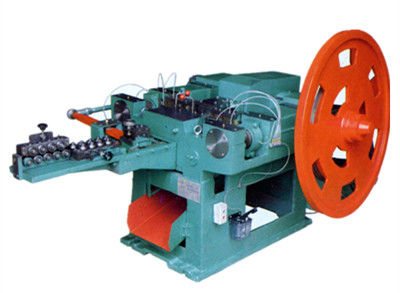

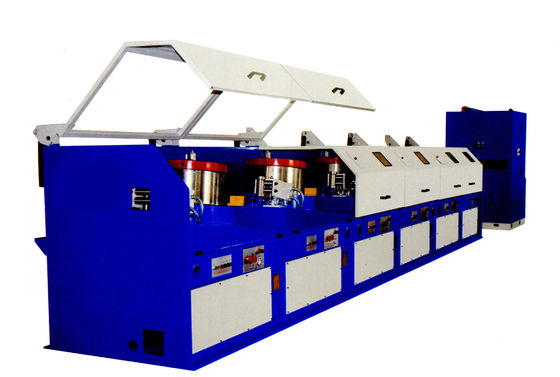

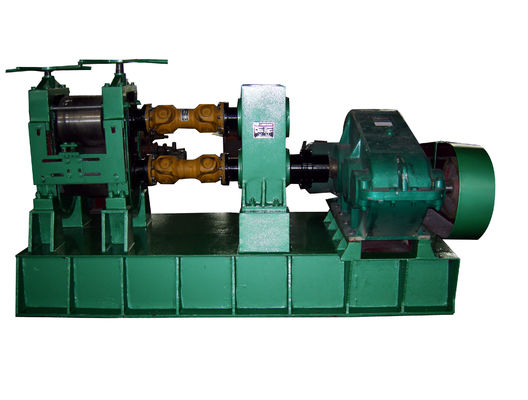

This advanced Wire Hanger Making Machine is specially designed for producing steel wire hangers used in laundries, garment factories, and retail stores. With its intelligent design and precision engineering, the machine offers smooth operation, high productivity, and consistent hanger quality.

High Efficiency and Precision

The Automatic Clothes Wire Hanger Making Machine operates with a designed capacity of 10–15 pieces per minute, capable of producing hangers ranging from 17 to 19 inches in size. It supports wire diameters of 4.0–4.5 mm and is powered by a 2.2 kW motor and a 2 kW servo motor, ensuring stable performance and low energy consumption.

Automatic Operation and Easy Control

All processes — including wire feeding, straightening, cutting, bending, and forming — are automatically completed. This minimizes manual handling and improves production efficiency. The system is easy to operate, making it ideal for both experienced manufacturers and new operators.

Durable and Reliable Structure

The machine is built with a sturdy frame and precision components, ensuring smooth operation and long service life. It is also equipped with safety features and a user-friendly control panel for convenient operation.

Wide Application and Customization

This Automatic Clothes Wire Hanger Making Machine is suitable for various types of clothes hangers, including laundry hangers, coat hangers, and retail display hangers. It is widely used in garment manufacturing plants, dry-cleaning shops, and metal forming industries. Customization is available to meet specific production needs.

Professional Service and Support

APEX Machinery offers comprehensive after-sales service including online technical support, video guidance, spare parts supply, and overseas engineer assistance. With a one-year warranty and lifetime support, customers can rely on fast response and professional solutions.

Packing and Delivery

The machine is securely packed for international shipment. Standard packaging includes one main machine (2.4×1.0×1.6 m) and one wire payoff unit (1.2×1.2×1.0 m). Delivery time and price can be negotiated according to customer requirements.

The Automatic Clothes Wire Hanger Making Machine represents the future of hanger production — efficient, precise, and fully automated. Whether for small-scale factories or large industrial operations, it helps manufacturers improve output quality, save labor, and achieve sustainable, long-term growth in the garment and laundry industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!