Product Description:

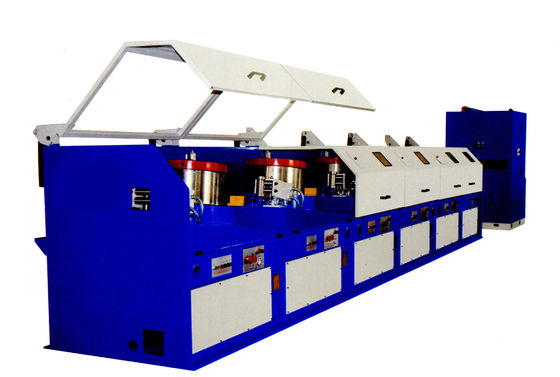

The Wire Drawing Machines offered are a state-of-the-art wire processing equipment designed to meet the demands of contemporary wire making industries. These sophisticated machines are engineered to transform large diameter wires into finer wires with an outlet diameter ranging from 0.8 to 5mm, which is essential for a wide range of applications in electronics, construction, and other industries. The precise engineering and robust construction of these machines ensure high efficiency and reliability, making them an indispensable asset in wire making machinery.

At the heart of these Wire Draw Machines is the advanced OTO pulley system. OTO, which stands for "over-the-top," refers to the configuration of the drawing pulleys that guide the wire in a smooth and controlled manner, ensuring the uniformity of the outlet diameter. This pulley system is renowned for its ability to maintain consistent tension and speed during the drawing process, which is critical for producing high-quality wire. The OTO pulley is a key feature that distinguishes these machines from other wire processing equipment in the market, providing unparalleled control over the wire drawing process.

Another core attribute of these Wire Drawing Machines is their state-of-the-art control system. Equipped with a Programmable Logic Controller (PLC), these machines offer precision control over the entire drawing process. The PLC allows for easy adjustments and fine-tuning of machine parameters, enabling operators to achieve the desired wire characteristics with ease. Additionally, the automation capabilities of the PLC result in reduced manual intervention, leading to increased production rates and reduced operational costs. The integration of the PLC not only enhances the functionality of the wire making machinery but also ensures consistent product quality and reliability.

The core components of these Wire Draw Machines also include the PLC as the central element. This highlights the importance of the control system in maintaining the performance and longevity of the machine. The PLC is responsible for coordinating the various components and processes, ensuring smooth operation and quick response to any changes in the production environment. The inclusion of high-quality core components, such as the PLC, is a testament to the commitment to durability and efficiency in wire processing equipment.

Shaping Mode is another critical aspect of these Wire Drawing Machines, which utilize compression mould technology. This method involves the application of compressive forces to shape the metal wire to the desired diameter as it is drawn through the dies. The compression mould shaping mode is particularly effective for creating uniform and precise wire diameters, which is essential for ensuring the quality of the end product. This shaping mode also contributes to the extended lifespan of the dies and reduces the wear and tear on the machine, thus enhancing the overall efficiency and reducing maintenance requirements.

In conclusion, the Wire Drawing Machines with an outlet diameter of 0.8 to 5mm, OTO pulley system, PLC control system, and compression mould shaping mode represent the pinnacle of wire processing equipment. Their robust design, precision control, and high-quality core components make them an invaluable addition to any wire making machinery fleet. Whether for the production of fine electronics wires or robust construction cables, these Wire Draw Machines are built to deliver unparalleled performance and exceptional wire quality, making them a smart investment for any company in the wire manufacturing industry.

Features:

-

Product Name: Wire Drawing Machines

-

Fan Power: 30W

-

Root Number: 1

-

Shaping Mode: Compression Mould

-

Wire Speed: 1.8 to 8 m/min

-

Pulley: OTO

-

Keywords: Wire Draw Machines, Wire Making Machinery, Wire Manufacturing Equipment

Technical Parameters:

|

Technical Parameter

|

Specification

|

|

Fan Power

|

30W

|

|

Wire Speed

|

1.8 To 8 M/min

|

|

Pulley

|

OTO

|

|

Key Selling Points

|

Easy To Operate

|

|

Max. Wire Diameter

|

10mm

|

|

Machinery Test Report

|

Provided

|

|

Frequency

|

50Hz

|

|

Root Number

|

1

|

|

Core Components

|

PLC

|

|

Power Source

|

Electric

|

Applications:

Wire Drawing Machines are a cornerstone in the world of Wire Manufacturing Equipment, and their applications are diverse and essential in various industrial scenarios. As a Hot Product of 2019, these machines have proven their worth and efficiency in the competitive market. The wire drawing process involves pulling wire through a series of dies to reduce its diameter, and this process is critical for producing high-quality wire in a multitude of dimensions and tensile strengths.

With a Shaping Mode that utilizes Compression Mould technology, Wire Drawing Machines create wire products that meet exact specifications with a high degree of precision. This process is essential in applications where the wire must have specific mechanical properties, such as in the production of springs, fasteners, and other critical components. The precision shaping capability of these machines makes them invaluable in industries that require exacting standards, such as automotive, aerospace, and electronics.

The inclusion of an OTO Pulley system in these Wire Drawing Machines ensures efficient and smooth wire processing. The OTO, or over-the-top, pulley arrangement allows for continuous drawing action, which is essential for high-volume production scenarios. This feature is particularly advantageous for manufacturers who need to maintain consistent tension and avoid wire breaks during the drawing process.

With a Root Number of 1, these machines are designed for individual wire processing, which allows for stringent control over the wire-drawing operation. This design is particularly useful for specialized applications where the quality of each wire is paramount. The singular focus of the machine on one wire at a time ensures that each product meets the highest standards before moving on to the next stage of manufacturing.

Capable of handling wire with a Max. Wire Diameter of 10mm, these Wire Drawing Machines are versatile enough to cater to a wide range of wire dimensions. This capability makes them suitable for a variety of Wire Coiling Machines applications, as they can produce wire that is ready for coiling into springs, cables, and other wire-based products. The robust design of these machines means they can handle both ferrous and non-ferrous materials, thereby broadening their application range even further.

In summary, the Wire Drawing Machines are indispensable in the field of Wire Manufacturing Equipment, offering high precision, versatility, and efficiency. Whether for electrical wiring, cable manufacturing, or intricate wire components in precision instruments, these machines provide the necessary functionality to meet the demands of modern wire production. Their application occasions and scenarios span across various industries, making them a critical asset for businesses looking to maintain a competitive edge in the market.

Customization:

Our Wire Drawing Machines offer a range of Product Customization Services to meet the specific needs of your manufacturing process. With a Shaping Mode of Compression Mould, our machines are designed to deliver precision and quality. The Electric Power Source ensures reliable and efficient operation, while the standardized Frequency of 50Hz aligns with global electrical standards.

The Root Number of 1 signifies that each machine is equipped with a single drawing position, ensuring focused and consistent tension in the drawing process. Our machines are capable of handling an Outlet Diameter range of 0.8~5mm, enabling a variety of wire sizes to be produced. Whether you are in the market for Wire Draw Machines, Wire Coiling Machines, or specialized Wire Coiling Machines, our customizable solutions are engineered to cater to your unique wire production requirements.

Support and Services:

Our Wire Drawing Machines are designed with precision and built for reliability, ensuring our customers can count on exceptional performance. We are committed to providing comprehensive technical support and services to maximize the efficiency and lifespan of your equipment. Our product technical support includes troubleshooting assistance, maintenance guidance, and tips for optimizing machine operations.

Our skilled technicians are available to offer remote support, providing step-by-step solutions to any operational challenges you may encounter. We aim to minimize downtime and ensure that your production processes are running smoothly. For more complex issues or regular maintenance, our service team can provide on-site assistance, ensuring that your Wire Drawing Machines receive the expert care they need.

To help you get the most out of your Wire Drawing Machines, we also offer training services for your staff. These training sessions cover everything from basic operation to advanced maintenance techniques, empowering your team with the knowledge to effectively manage the equipment. Additionally, we provide access to a range of resources, including manuals, how-to guides, and FAQs, to support your ongoing needs.

For the longevity of your machines, we supply genuine spare parts that meet the highest standards of quality. Our inventory management system ensures that necessary parts are always in stock, allowing for swift replacement and repair. We also offer upgrade services to enhance the capabilities of your existing machinery, keeping it up to date with the latest technological advancements.

Our commitment to your satisfaction doesn't end with the sale of our Wire Drawing Machines. We remain at your service throughout the entire lifecycle of the product, dedicated to delivering the support and services needed to maintain optimal performance. Our technical support team is ready to assist you with any inquiries or issues, ensuring your equipment continues to contribute to the success of your operations.

Packing and Shipping:

The Wire Drawing Machines are meticulously packed to ensure their protection during transportation. Each machine is encased in a robust wooden crate, tailored to its dimensions, providing a secure barrier against impacts and vibrations. The interior of the crate is fortified with shock-absorbing materials to prevent any movement that could cause damage to the equipment.

Before shipping, each crate is sealed and weatherproofed to keep the machine safe from moisture and environmental hazards. The crates are then labeled with handling instructions and shipping details to facilitate careful handling and efficient tracking during transit.

Our logistics team oversees the shipping process, choosing reliable carriers with experience in handling heavy industrial machinery. We provide our customers with tracking information and estimated delivery dates. Our aim is to ensure that your Wire Drawing Machine arrives on time and in perfect working condition, ready for immediate operation.

FAQ:

Q1: What types of wire can the Wire Drawing Machine process?

A1: Our Wire Drawing Machines are capable of processing a wide range of metals including steel, copper, aluminum, and alloy wires. Depending on the specific machine model, it can handle different wire diameters and material properties.

Q2: What are the power requirements for the Wire Drawing Machine?

A2: Power requirements vary by model. Generally, our machines operate on industrial electricity standards such as 380V, 400V, or 480V, 3-phase power. It's important to check the specific power requirements for the machine you are interested in.

Q3: Can the Wire Drawing Machine be customized to fit specific production needs?

A3: Yes, we offer customization options for our Wire Drawing Machines to meet specific production requirements. This includes modifications to handle different wire sizes, lengths, and speeds. Please contact us with your specific needs, and our engineering team will work with you to create a machine that fits your requirements.

Q4: What is the maximum drawing speed of the Wire Drawing Machine?

A4: The maximum drawing speed can vary significantly depending on the machine model and the type of wire being processed. We have machines that range from moderate speeds for delicate materials to high-speed machines for efficient mass production. Please consult the product specifications for the exact speed capabilities.

Q5: How does the Wire Drawing Machine ensure consistent wire quality?

A5: Our Wire Drawing Machines incorporate advanced control systems and precision components that regulate tension and speed throughout the drawing process. Additionally, many models feature inline monitoring and quality control systems to ensure that the wire meets stringent quality standards.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!